By John Abercrombie

Hoses2U Owner

In the intricate dance of an industrial business, each component plays a crucial role in maintaining optimal productivity. One such often-underestimated element is the hydraulic hose. Though small, a failed hydraulic hose can unleash a series of disruptions that reverberate across the entire operation, halting productivity and causing financial losses. In this article, we will delve into how a seemingly insignificant hydraulic hose failure can lead to a significant interruption in industrial productivity.

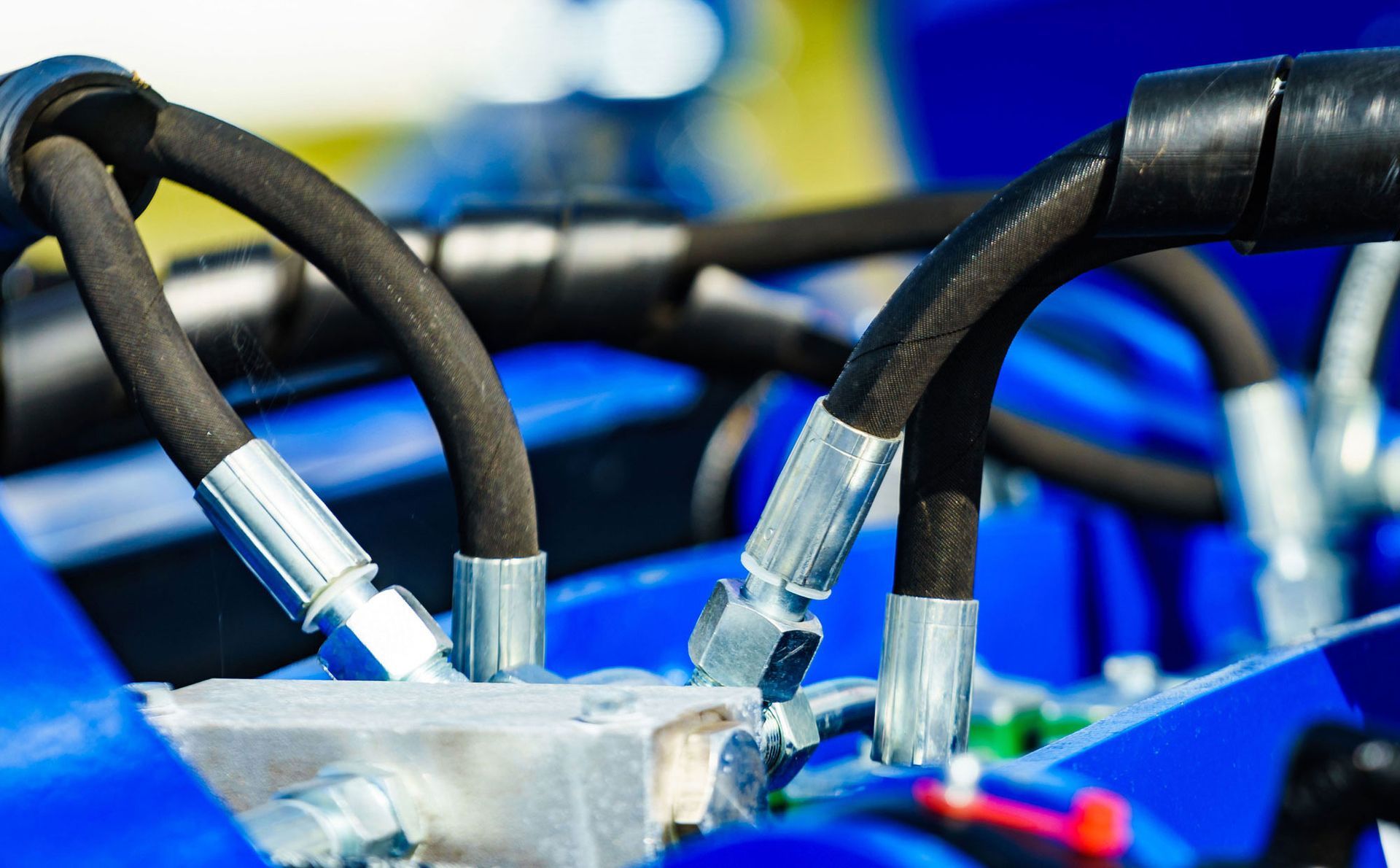

The unsung hero: hydraulic hoses

Hydraulic hoses are the lifelines of many industrial applications, responsible for transmitting fluid power within machinery and equipment. These hoses enable the efficient transfer of power, ensuring smooth functioning of various processes like lifting, bending and rotating heavy loads. Their importance becomes more apparent when we consider the impact of their failure on industrial operations.

The domino effect of failure

Imagine a scenario in a manufacturing plant where heavy machinery carries out precision tasks. A hydraulic hose, worn out over time due to continuous use, suddenly gives way. This seemingly minor event initiates a cascade of disruptions that can significantly affect productivity.

Downtime: The most immediate impact of a failed hydraulic hose is the downtime it causes. Machinery comes to a grinding halt, leading to idle workers, missed deadlines and a sudden drop in overall productivity.

Maintenance delays: Replacing a hydraulic hose might seem like a straightforward task, but in a complex industrial environment, it often involves skilled technicians, specialized tools and replacement parts. Sourcing these components and professionals can lead to extended periods of machinery inactivity.

Production backlog: The halted machinery disrupts the production schedule, leading to a backlog of unfinished orders. Catching up with this backlog can be a daunting task that requires overtime work, increased stress on remaining machinery and quality control issues.

Financial impact: Lost production hours, maintenance expenses and overtime wages can all lead to a substantial financial burden on the business. Moreover, missed delivery deadlines can strain customer relationships, potentially resulting in order cancellations or loss of future business.

Ripple effects: The impact doesn't end within the factory walls. Delays in production can lead to supply chain disruptions, affecting downstream manufacturers, suppliers, and customers who depend on timely deliveries.

Prevention and mitigation

The key to avoiding the detrimental effects of a failed hydraulic hose lies in proactive maintenance and regular inspections. Implementing a comprehensive preventive maintenance program that includes routine checks and timely replacements can significantly reduce the risk of hose failures. Investing in high-quality hoses and fittings can also extend the lifespan of these critical components.

Conclusion

In the tapestry of industrial productivity, every thread counts. The humble hydraulic hose, often overlooked, can wield the power to disrupt an entire operation if neglected. By recognizing the potential consequences of a failed hydraulic hose and taking steps to prevent such failures, industrial businesses can maintain a smooth workflow, preventing financial losses.

Remember, Hoses2U performs emergency, onsite hose-replacement 24/7/365. We’re always on call, waiting to hear from you. We offer a one-hour ETA. Contact us anytime at (720) 710-4441.